Tuesday, January 31, 2023

CIMTEC engineers have been solving machine tending and palletizing solutions for years. Our customers continue to see a return on their investment by using robots for mundane repetitive tasks, allowing their skilled workers to focus on more important ones.… Read More »

CIMTEC engineers have been solving machine tending and palletizing solutions for years. Our customers continue to see a return on their investment by using robots for mundane repetitive tasks, allowing their skilled workers to focus on more important ones.… Read More »

Tuesday, April 5, 2022

With the advent of industry 4.0 and exponentially advancing technology, the manufacturing sector has grown into an extremely high-tech field with specialized talent needs, especially in the critical skill shortage areas of manufacturing engineering.

With the advent of industry 4.0 and exponentially advancing technology, the manufacturing sector has grown into an extremely high-tech field with specialized talent needs, especially in the critical skill shortage areas of manufacturing engineering.

CIMTEC Automation worked with AMTEK to bring collaborative robots to the classroom for IALR.… Read More »

Tuesday, January 11, 2022

While impressive advancements in plastics and rubber technology have created new profit opportunities for manufacturers in the space, falling production costs and improving logistical connections have simultaneously reduced barriers to entry for competitive manufacturers in Asia, Latin America, and the Near East.… Read More »

While impressive advancements in plastics and rubber technology have created new profit opportunities for manufacturers in the space, falling production costs and improving logistical connections have simultaneously reduced barriers to entry for competitive manufacturers in Asia, Latin America, and the Near East.… Read More »

Monday, December 6, 2021

As collaborative robots emerge as the fastest growing segment of industrial automation, industry recognized robots are increasingly sought after in schools and manufacturing programs.

As collaborative robots emerge as the fastest growing segment of industrial automation, industry recognized robots are increasingly sought after in schools and manufacturing programs.

Getting students real world experience before they enter the workforce is a priority for every educational institution.… Read More »

Friday, October 8, 2021

CIMTEC engineers have known that the benefits of collaborative automation are undisputed – more profitability, productivity, flexibility, higher quality, and even more employee satisfaction. Given the current economic landscape, manufacturers need these advantages now more than ever.… Read More »

CIMTEC engineers have known that the benefits of collaborative automation are undisputed – more profitability, productivity, flexibility, higher quality, and even more employee satisfaction. Given the current economic landscape, manufacturers need these advantages now more than ever.… Read More »

Friday, October 8, 2021

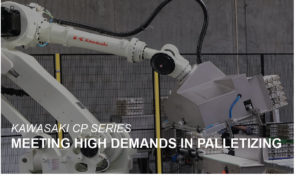

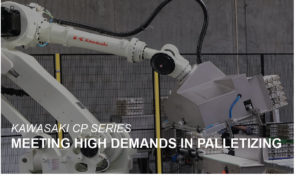

Designed specifically for palletizing applications, Kawasaki’s palletizing robot line consists of five unique models with payload capacity from 80 kg to 700 kg to suit most needs. With industry leading work range, reliability, and speed, Kawasaki’s palletizing robots help companies improve production line efficiency.… Read More »

Designed specifically for palletizing applications, Kawasaki’s palletizing robot line consists of five unique models with payload capacity from 80 kg to 700 kg to suit most needs. With industry leading work range, reliability, and speed, Kawasaki’s palletizing robots help companies improve production line efficiency.… Read More »

Wednesday, July 7, 2021

We love it when our robots and sensors team up. An industrial imaging and robotic automation company needed a vision system that could communicate directly with controllers for their inline production changes. CIMTEC has solved many challenges like this one for a variety of automation companies.… Read More »

We love it when our robots and sensors team up. An industrial imaging and robotic automation company needed a vision system that could communicate directly with controllers for their inline production changes. CIMTEC has solved many challenges like this one for a variety of automation companies.… Read More »

Thursday, June 17, 2021

Getting students real world experience before they enter the workforce is a priority for every educational institution. Now, with this collaborative team of cobots, they are getting just that. CIMTEC Automation partners with MiR and Universal Robots to provide the first industrial recognized collaborative offering for universities with special university pricing.… Read More »

Getting students real world experience before they enter the workforce is a priority for every educational institution. Now, with this collaborative team of cobots, they are getting just that. CIMTEC Automation partners with MiR and Universal Robots to provide the first industrial recognized collaborative offering for universities with special university pricing.… Read More »

Thursday, June 17, 2021

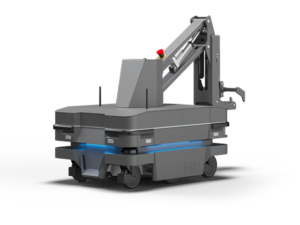

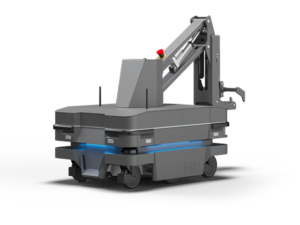

MiR250 Hook is ideal for a wide range of towing jobs, such as efficiently moving heavy products between locations in a manufacturing facility or warehouse or moving linen and food carts in hospitals. The MiR250 Hook supports the transport of loads up to 500 kg (1100 lbs.),… Read More »

MiR250 Hook is ideal for a wide range of towing jobs, such as efficiently moving heavy products between locations in a manufacturing facility or warehouse or moving linen and food carts in hospitals. The MiR250 Hook supports the transport of loads up to 500 kg (1100 lbs.),… Read More »

Monday, May 17, 2021

The C12XL 6-axis robot from Epson Robots is the company’s highest payload, highest reach robot and CIMTEC engineers are excited about this one! With its high reach and lightweight body, this robot is ready to work for packaging, kitting, machine tending or palletizing.… Read More »

The C12XL 6-axis robot from Epson Robots is the company’s highest payload, highest reach robot and CIMTEC engineers are excited about this one! With its high reach and lightweight body, this robot is ready to work for packaging, kitting, machine tending or palletizing.… Read More »

CIMTEC engineers have been solving machine tending and palletizing solutions for years. Our customers continue to see a return on their investment by using robots for mundane repetitive tasks, allowing their skilled workers to focus on more important ones.… Read More »

CIMTEC engineers have been solving machine tending and palletizing solutions for years. Our customers continue to see a return on their investment by using robots for mundane repetitive tasks, allowing their skilled workers to focus on more important ones.… Read More »

With the advent of industry 4.0 and exponentially advancing technology, the manufacturing sector has grown into an extremely high-tech field with specialized talent needs, especially in the critical skill shortage areas of manufacturing engineering.

With the advent of industry 4.0 and exponentially advancing technology, the manufacturing sector has grown into an extremely high-tech field with specialized talent needs, especially in the critical skill shortage areas of manufacturing engineering. While impressive advancements in plastics and rubber technology have created new profit opportunities for manufacturers in the space, falling production costs and improving logistical connections have simultaneously reduced barriers to entry for competitive manufacturers in Asia, Latin America, and the Near East.…

While impressive advancements in plastics and rubber technology have created new profit opportunities for manufacturers in the space, falling production costs and improving logistical connections have simultaneously reduced barriers to entry for competitive manufacturers in Asia, Latin America, and the Near East.…

Designed specifically for palletizing applications, Kawasaki’s palletizing robot line consists of five unique models with payload capacity from 80 kg to 700 kg to suit most needs. With industry leading work range, reliability, and speed, Kawasaki’s palletizing robots help companies improve production line efficiency.…

Designed specifically for palletizing applications, Kawasaki’s palletizing robot line consists of five unique models with payload capacity from 80 kg to 700 kg to suit most needs. With industry leading work range, reliability, and speed, Kawasaki’s palletizing robots help companies improve production line efficiency.…  We love it when our robots and sensors team up. An industrial imaging and robotic automation company needed a vision system that could communicate directly with controllers for their inline production changes. CIMTEC has solved many challenges like this one for a variety of automation companies.…

We love it when our robots and sensors team up. An industrial imaging and robotic automation company needed a vision system that could communicate directly with controllers for their inline production changes. CIMTEC has solved many challenges like this one for a variety of automation companies.…  Getting students real world experience before they enter the workforce is a priority for every educational institution. Now, with this collaborative team of cobots, they are getting just that. CIMTEC Automation partners with MiR and Universal Robots to provide the first industrial recognized collaborative offering for universities with special university pricing.…

Getting students real world experience before they enter the workforce is a priority for every educational institution. Now, with this collaborative team of cobots, they are getting just that. CIMTEC Automation partners with MiR and Universal Robots to provide the first industrial recognized collaborative offering for universities with special university pricing.…  MiR250 Hook is ideal for a wide range of towing jobs, such as efficiently moving heavy products between locations in a manufacturing facility or warehouse or moving linen and food carts in hospitals. The MiR250 Hook supports the transport of loads up to 500 kg (1100 lbs.),…

MiR250 Hook is ideal for a wide range of towing jobs, such as efficiently moving heavy products between locations in a manufacturing facility or warehouse or moving linen and food carts in hospitals. The MiR250 Hook supports the transport of loads up to 500 kg (1100 lbs.),…  The C12XL 6-axis robot from Epson Robots is the company’s highest payload, highest reach robot and CIMTEC engineers are excited about this one! With its high reach and lightweight body, this robot is ready to work for packaging, kitting, machine tending or palletizing.…

The C12XL 6-axis robot from Epson Robots is the company’s highest payload, highest reach robot and CIMTEC engineers are excited about this one! With its high reach and lightweight body, this robot is ready to work for packaging, kitting, machine tending or palletizing.…