CIMTEC customers are always looking for ways to stay ahead of technology and bring efficiency and cost effectiveness to their production lines. Our state-of-the-art sensor products are what sets us apart from our competitors. Now it’s possible to capture motion without contact. The SPEETEC® from SICK opens up new possibilities for measuring sensitive, soft, or smooth objects.

CIMTEC customers are always looking for ways to stay ahead of technology and bring efficiency and cost effectiveness to their production lines. Our state-of-the-art sensor products are what sets us apart from our competitors. Now it’s possible to capture motion without contact. The SPEETEC® from SICK opens up new possibilities for measuring sensitive, soft, or smooth objects.

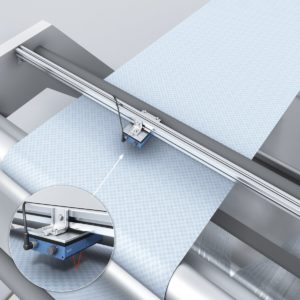

The SPEETEC expands upon product offerings for speed and length measurement of objects moving in a linear path to include technology that measures directly on the material surface. The non-contact sensor is able to measure a wide range of web and continuous materials, as well as blanks with an accuracy of just 4 µm.

The SPEETEC® from SICK is an innovative, non-contact sensor for speed and length measurement of objects moving in a linear path — Slip-resistant, without measuring elements, without damaging sensitive surfaces and without wear and tear on tactile sensor elements.

Special Materials Sensing

For sensitive, soft, or smooth surfaces, customers from factory or logistics automation require non-contact measurement options for the length, speed, and position of continuous webs and blanks. Optical scanning prevents damage or contamination, thereby increasing product quality.

The SPEETEC® offers a new way to measure without slip, measuring elements or marking, and wear and tear on tactile sensor elements. Materials that cause wear, adhesion, or abrasion damage to measurement solutions such as measuring wheel encoders, impairing their function, can be measured by the SPEETEC® with a high degree of process reliability and availability.

Highly Accurate Measurement Principle

Since the SPEETEC® is equipped with Class 1 lasers, it offers an alternative to expensive laser velocimeters and the associated costly protective measures. The return on investment (ROI) is particularly attractive. For the SPEETEC®, this is less than a year.

The non-contact measurement is performed with a laser Doppler process at speeds of up to 10 m/s. Two transmitters emit laser light – one in the direction of movement of the material, the other in the opposite direction. Since the transmitters work independently, possible mounting tolerances and surface fluctuations (i.e., with wavy surfaces) can be balanced out.

All measurements are done with high precision. At a resolution of four micrometers, the accuracy relating to the object length of a meter is one millimeter. The repeatability in this case is specified with a half a millimeter. Measured values are output via the TTL or HTL interfaces common in the encoder world, making integration easy.

SPEETEC Features at a glance:

- Ensures a high level of product quality by using optical sensors, avoiding damage and contamination to the surfaces being measured

- The Class 1 laser saves costs as no additional laser protection measures are required.

- High measurement accuracy and reproducibility, including in start-stop operation at short measurement lengths

- Optimized productivity and process quality through measurement without slippage

- Broad range of applications thanks to compatibility with many materials, colors and surfaces, as shown above

CIMTEC engineers are trained and experienced with all of the SICK line of products, let us show you the power behind the SICK SPEETEC. 877.524.6832