Legacy industrial automation systems must eventually be ripped and replaced or upgraded. See four challenges and five benefits of upgrades using modern controllers.

Legacy industrial automation systems must eventually be ripped and replaced or upgraded. See four challenges and five benefits of upgrades using modern controllers.

As experts in PLC system conversion, CIMTEC has made thousands of successful migrations, enabling our clients to stay highly competitive while slashing the staggering expense of downtime. With new modern controllers on the market, the need for a full migration has taken a backseat in lieu of upgrades, easing the pain of costs and downtime for your facility.

This article written by Vibhoosh Gupta for Control Engineering magazine details the challenges and benefits of upgrades using modern controllers.

_______

Much of the consumer world is comfortable with frequent upgrades of their mobile electronics and associated apps. Even for some more expensive consumer goods such as big-screen TVs, the cheapest and easiest path forward is discarding the problem item and buying a new one. However, the case is much different for industrial automated machinery and systems.

Industrial equipment is built to run for decades. Many mechanical elements are selected so they can be rebuilt or replaced with little difficulty. However, the automation system hardware and software used for such equipment can become difficult to maintain, resulting in increased unplanned downtime.

When, or hopefully before, automation systems become unsupportable, users are faced with ripping and replacing or upgrading and integrating a new automation system. Both modernization options can be difficult, time-consuming and expensive. However, some vendors have developed newer controllers and automation platforms with the end user upgrade path in mind. This makes it far more attractive to undertake an automation system upgrade while protecting existing investments.

Driving factors for controller upgrades

An industrial automation system, even with a reasonable availability of spare parts and skilled expertise, can only operate for a finite period of time. Numerous reasons factor into the upgrade decision:

- Lack of product availability

- Excessive downtime

- Diminished productivity

- Lost knowledge

- Workforce stagnation

- Increased cyber risk.

A lack of available spare parts is an obvious condition prompting an upgrade. Not only does specialty industrial hardware become difficult to source, but the same is true for PC subcomponents, operating systems (OSs), configuration software packages and drivers.

Aging automation systems are more prone to failure, and breakdowns cause downtime to add up. Even when legacy systems can be kept running, they may not facilitate operating at peak capacity. There also is less opportunity for users to add productivity-increasing improvements like mobile visualization, remote monitoring, and advanced outcome optimizing controls.

From a human resources standpoint, there are two subtle, but related, forces acting as drivers advancing the case for upgrades. The first involves lost knowledge due to a retiring workforce who have legacy-specific skills that are difficult to transfer to newer employees. The second can be a form of workforce stagnation where younger employees seek to work on modern systems and will avoid perceived dead-end positions taking over legacy systems.

A common cyber-attack weakness is an unavoidable concern for legacy systems designed before the proliferation of networking connectivity, but which now may be connected to the internet or other systems capable of compromising an operation.

Sometimes legacy automation systems are called “classic” as if they were a museum-quality 50-year old airplane or car. However, the reality of supporting legacy systems is the effort can be a downward spiral of inefficiency, cost and wasted effort. An upgrade path should be researched, determined and agreed-upon before this point is reached.

Migration or upgrade? Similar or better?

When users investigate a path forward for legacy automation systems reaching end-of-life, they must consider hardware and software. Hardware upgrades are conceptually straightforward, but field constraints can make them very difficult to physically perform. Software upgrades are complicated when multiple control, visualization, and communications configurations are involved. The terms migration and upgrade are sometimes used interchangeably, and there is a gray area between them.

Rip-and-replace migrations discard all existing hardware and software, completely replacing it from scratch. Re-engineering efforts may include adding and deleting functions. Sometimes migrations use software and procedures attempting to convert functionality one-for-one in a like-for-like manner.

Upgrading, on the other hand, implies a rethinking of the system using contemporary means and methods. It can be executed as more of an evolution performed at a controlled pace as opposed to a drastic change.

A balanced upgrade solution is possible in some cases and presents a better approach. The ideal scenario is to upgrade existing hardware, software, and networking elements to contemporary platforms capable of directly operating the existing code with minimal effort. This ensures a fast and direct executed migration with minimal risk, while future-proofing the system by enabling future upgrades.

Four potential upgrade problems

While end users may not be happy dealing with the consequences of an aging legacy system, they also are wise to consider the difficulties an upgrade can introduce.

When an automation system is designed, it requires the coordinated efforts of several disciplines including those who understand the machinery or process equipment, electrical designers, programmers and installers. For upgrades, many of those same skills are needed as well as careful field coordination to minimize operational impacts.

Four typical challenges for industrial automation upgrades are:

- Form factor constraints

- Field wiring adaptations

- Software code conversion impacts

- Downtime caused by outcomes of the preceding three items.

Existing automation systems are often in space-constrained cabinets, and the equipment area may have minimal working space. Fortunately, many newer automation components are smaller and run cooler than the legacy parts they replace. Some are engineered to fit in the exact same footprint, crucial to reducing downtime during an upgrade.

Even when enough space is available, existing field wiring may be hard to rework, fragile and not well tagged. Involving field wiring can consume substantial amounts of field labor and introduce risk, requiring every loop to be manually rechecked. Therefore, any means of allowing field wiring to remain in place to the greatest extent possible, such as the ability to reuse existing input/output (I/O) modules, provides the best option.

Translating software code for an upgrade is often considered a significant unknown. Existing control and supervisory programs are in place, working, and tested. Any upgrade path requiring re-coding takes significant programmer effort, introduces risk, and may require a complete system retest — much like when the system was originally commissioned. In some cases, it may be impossible to determine the original functional definition as a basis, or maybe the available source code is poorly commented.

It is hard to completely evaluate translated software effectiveness in advance of cutover and actual connection in the field. Problems discovered during cutover can lead to extended downtime. This is why proven code conversion utilities, which enable users to execute one-click legacy program upgrades, are so important.

Five benefits outweigh effort

Newer industrial automation platforms provide higher performance, security, and availability than legacy systems. Modern controllers with specific features targeting the challenges of upgrading can make the final decision to change control platforms much easier (see sidebar).

Despite the challenges, there are many benefits from upgrading, including:

- Improved productivity

- Reduced operating costs

- Enhanced experience

- Increased cybersecurity

- Newly available insights.

Current processors and software code are part of the reason, while the latest architectural advancements can deliver redundancy and expandability not possible with older platforms. Because modern hardware, software, and networking is more reliable and accessible, this leads to reduced costs.

Contemporary tools and standards are often easier to use and more flexible than legacy systems, but training for users of newer platforms is still recommended.

More difficult to quantify but certainly of importance are the available insights arising from upgraded automation platforms. Extended diagnostics can help users operate their systems better, discover problems sooner, and troubleshoot them more effectively. Improved connectivity means it is easier to analyze available data, and even implement mobile and remote visualization to help users effectively operate.

Modern controllers ease upgrades

Any industrial automated system remaining in operation long enough will become a candidate for a control platform modernization. End users must compare the mounting costs and risks of a faltering legacy system against the projected expense and potential difficulties of modernizing.

One typical option, while expensive and risky, is a drastic migration where hardware and software are completely revamped. For a more balanced approach, end users should look at automation platforms offering a hardware and software upgrade path enabling a rapid execution and providing extended future capabilities. This provides the lowest risk way to ensure a quick cutover, enables future-proofing the platform, and makes it feasible to add other improvements such as remote access.

Controller upgrade example: Target the upgrade challenges

When technologies are designed for backwards compatibility, this can increase the ease of upgrading older systems. The downside of backwards compatibility is the risk of accommodating too much legacy technology and reducing the new system’s performance and capabilities. The best of both worlds occurs when the newer system can accept older connections and programming, while enabling an expanded feature set.

Some suppliers carefully consider the upgrade path of their systems because of the benefits it provides to their customers. Emerson’s Machine Automation Solutions business unit took this approach with its latest programable logic controller (PLC) systems acquired from General Electric.

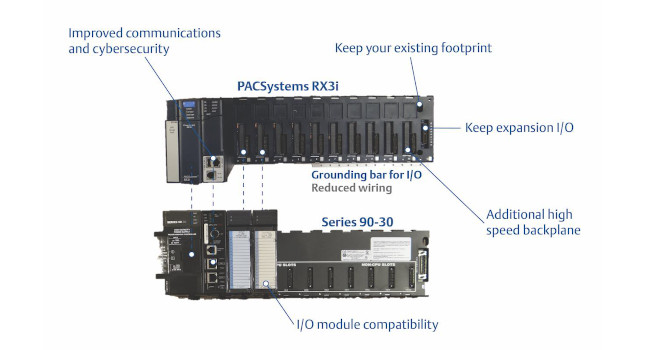

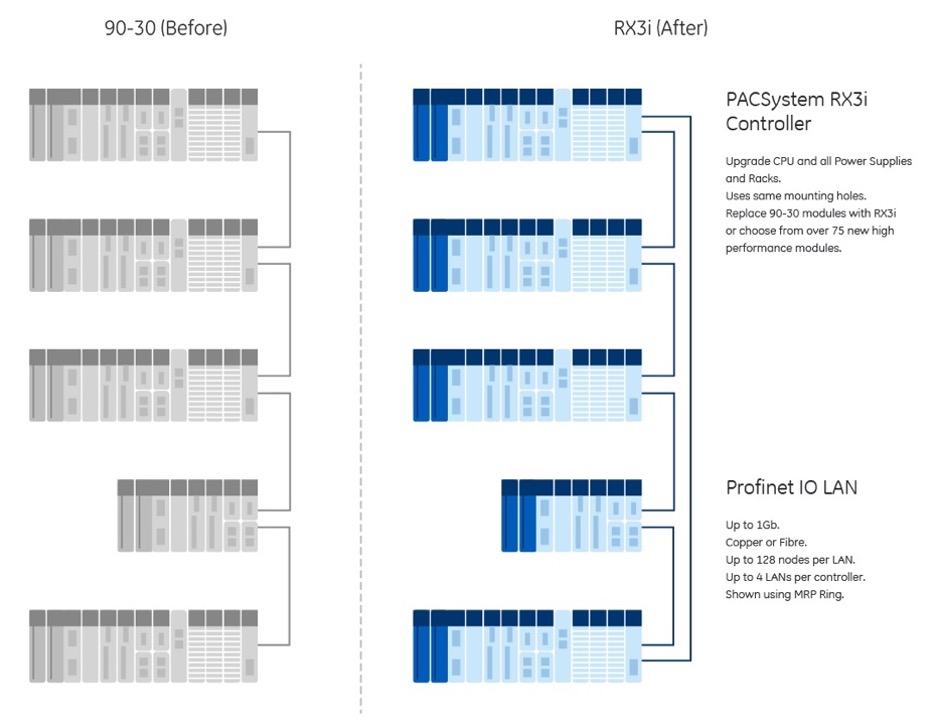

Many existing customers have General Electric 90-30 PLCs in operation. The latest Emerson PLC offering is the RX3i platform, which also includes the sophisticated outcome optimizing controller (OOC).

Emerson made sure the newer platform used the same footprint and mounting holes as the older platform. Furthermore, the backplanes have dual connectors to accept existing legacy I/O modules or a newer class of I/O modules on the same rack.

The most compelling feature of using these upgraded components are the software conversion utilities, which allow existing code to operate in the new platform with no changes. After an upgrade is complete, users can add advanced features at their own pace.

_______

When you partner with CIMTEC, you can rely on 30 years of experience in engineering, automation and PLCs. We’ll supply you with all the tools you need. Whether it’s a phased migration approach or an upgrade, we provide a detailed roadmap and walk our clients through every step of the conversion process.

Contact CIMTEC and to find out more about modern controller upgrades 877.524.6832